Laser cutting technical fabrics - minimal waste, prevents fraying, intricate designs

Technical fabrics are developed for their performance rather than their appearance. These fabrics are designed to offer functionality, such as durability, breathability, absorption, waterproofing, auditory protection, fire resistance, or antimicrobial properties.

They are commonly used in sportswear, protective clothing, medical textiles, automotive and marine interiors, and industrial applications.

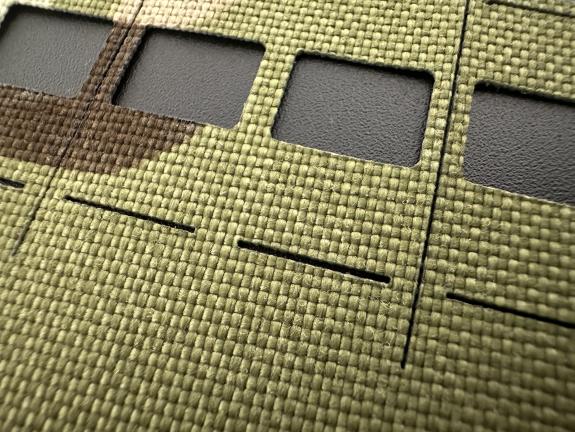

The key benefits of laser cutting technical fabrics includes low tolerance cutting with minimal fabric waste, sealed edges to prevent fraying, the ability to cut intricate designs, fast processing speeds and the flexibility to work with various technical fabric types.