Laser cutting and CNC cutting are two different methods used for cutting and shaping materials. Here are the key differences between the two:

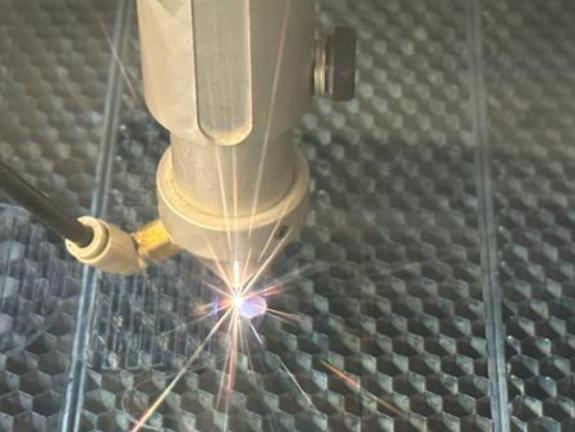

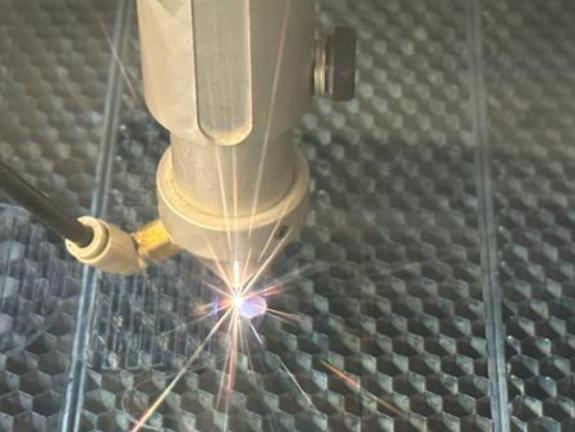

Laser cutting uses a high-powered laser beam to melt, burn, or vaporize the material, resulting in precise cuts. CNC cutting, on the other hand, moves a cutting tool across the material to create the desired shape or cut.

Laser cutting is known for its high precision and ability to create intricate designs and sharp corners, as the laser beam can make very fine cuts with minimal material distortion. In addition, CNC cutting is often used for 3D carving and deep cutting.

Laser cutting is generally faster than CNC cutting when it comes to cutting thin materials, as the laser beam can move quickly and cut through with high speed. CNC cutting is known for its efficiency in removing larger amounts of material, making it suitable for heavy duty cutting tasks.

Laser cutting can work with a wide range of materials, including wood, acrylic, fabric, and specialist fabrics. It is particularly well-suited for engraving tasks and working with delicate materials. CNC cutting, while also versatile, may have limitations with certain materials and may not be ideal for engraving.

In summary, laser cutting is best suited for precise and intricate cuts, engraving, and working with a variety of materials. CNC cutting, on the other hand, is more efficient for heavy-duty cutting tasks and 3D carving. Both methods have their strengths and weaknesses, and the choice between them depends on the specific requirements and materials involved.

Sources: cncsourced.com